HMT MACHINE TOOLS LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HMT MACHINE TOOLS LTD

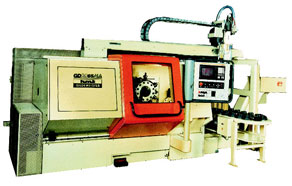

Cnc Chuckers

Bringing economy, precision and speed into heavy machine shop.

Salient Features :

Optimally designed cost effective high productive chucker offering wide range of manufacturing solutions while meeting stringent quality requirements.

Comprises of two main spindle heads, with 8-station bidirectional turret mounted on compound sides for each spindle. This configuration enables the two main spindles to independently carry out machining operations on two components or on both sides of the sam e component simultaneously, thus eliminating intermediate storage, and virtually doubling the production.

Capable of turning variety of bar and chucking components involving straight and taper turning, drilling, boring, contouring, internal, and external threading, etc. Ideal for turning, boring, drilling and threading operations on components with length to diameter ratio of less than one.

Gearless headstock with spindle supported on high precision angular contact ball bearings and is driven by AC spindle motor.

Slides controlled with an AC servo system and are provided with low friction guideways.

Hydraulic chucking of the work ensures quick and rigid gripping during high metal removal.

Provides high degree of flexibility in machining components like gear blanks, housings, bearing races, etc. with dia. Up to 200 mm.

Ideal CNC chucker for economic machining in not only medium and large production but also justifies small batch production, through quick change over time.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.